? Date: November 12th – 15th ? Booth: C6.303 We are excited to announce that we will be attending electronica 2024, the world’s leading trade fair for electronics. This year, we’ll be presenting our latest innovations in electronic components, connectors, and automation solutions tailored to industries such as automotive, industrial automation, marine, and energy storage. […]

Dear Customers and Partners, We are pleased to inform you that electronica China has officially opened today! The exhibition will last until July 10th. This high-profile industry event provides an excellent opportunity to showcase the latest innovations and products, network with your peers and establish deeper business contacts. Dosin invites you to join the electronica, […]

Dear Customers and Partners, As the Chinese New Year approaches, we would like to inform you that our manufacturing facilities will be closed to celebrate this important holiday. Closure Dates: February 7th to February 16th, 2024 We will be back in full operation on February 17th. For any urgent matters during this period, please don’t […]

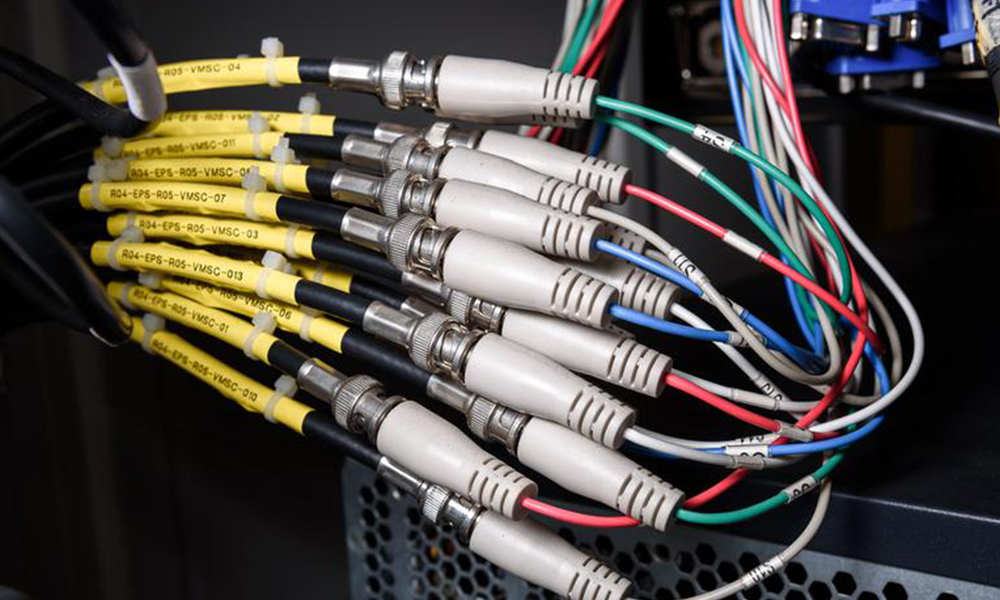

When we use the speaker, often the first thing to face is to connect the line, in addition to the power cord we are more familiar with, the rest of a bunch of dense variety of audio interfaces, some people may not know how to wire. These interfaces are not only different functions, more headaches […]

In recent years, with the rapid development of wireless communication and radar technology, increasing the transmission distance of a system requires a corresponding increase in its transmission power. As part of the entire microwave system, RF coaxial connectors need to be able to withstand the transmission requirements of high power. Simultaneously, RF engineers also frequently […]

Dear Customers and Partners, We are pleased to announce our company’s upcoming participation in the electronica South China from October 30th to November 1st! This is a high-profile industry event that provides us with an excellent opportunity to showcase the latest innovations and products, network with peers, and establish deeper business contacts. Show Overview Electronica […]

Radio Frequency (RF) connectors are key to transmitting RF signals and are widely used in wireless communications, microwave communications, satellite communications, radar systems and other RF equipment. This article discusses the development of RF connectors and their important applications in microwave components, taking SMP connectors as an example. RF Connectors RF connectors are components that […]

Dear Valued Customers and Partners, As the Mid-Autumn Festival and National Day approach, we would like to inform you that our office will be closed from September 29, 2023, to October 3, 2023. We will resume our regular business operations on October 4, 2023. Should you have any urgent matters during this period, please do […]

RF connectors are an important component used to connect RF circuits, and their performance has a significant impact on the stability and reliability of the overall RF system. However, with the passage of time and frequent use, RF connectors are subject to wear and tear, which adversely affects their performance. In this paper, we will […]