RF connectors are an important component used to connect RF circuits, and their performance has a significant impact on the stability and reliability of the overall RF system. However, with the passage of time and frequent use, RF connectors are subject to wear and tear, which adversely affects their performance. In this paper, we will analyze in detail the performance changes of RF connectors after wear and its influencing factors, and propose corresponding solutions.

Types and Structures of RF Connectors

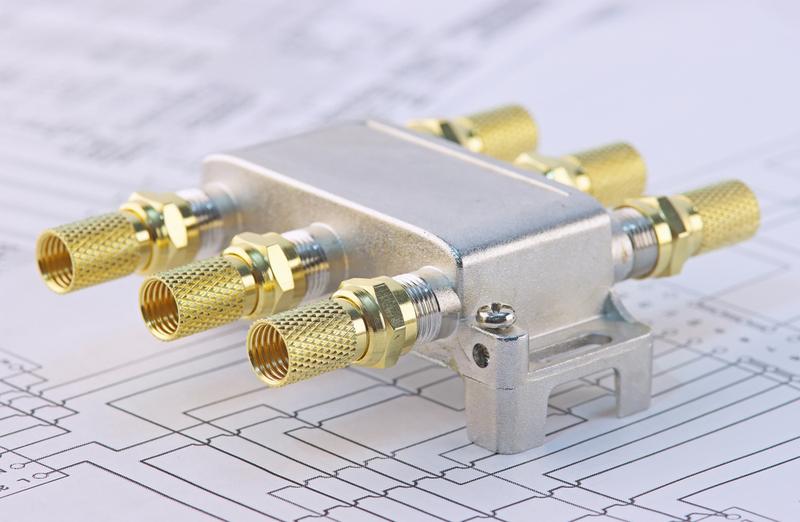

An RF connector is an electrical component that transmits RF signals to a specific header. It usually consists of a center lead, an outer conductor, an insulating material, a connecting thread and a gasket. Depending on the connector connection method, it can be divided into various types such as bayonet connectors (BNC, etc.), threaded connectors (N-type, TNC, SMA, etc.), and quick-lock connectors (MCX, MMCX, etc.).

Reasons for RF Connector Wear

RF connectors are subject to wear and tear of the contact parts due to frequent plugging and unplugging, environmental factors and other factors. Wear will lead to the connector internal metal surface loss of finish, the contact area becomes smaller, resulting in the tightness of the connection and stability decline. The main reasons for RF connector wear are as follows.

Environment: The environment in which the equipment is used is also an important factor in RF connector wear. For example, vibration, high temperature, humidity and corrosion can accelerate the wear of RF connectors, thus affecting their performance.

Interface plugging and unplugging times: RF connector interface plugging and unplugging times is also one of the most important causes of wear and tear. If the number of insertion and removal is too many, the contact part of the metal surface will become rough and uneven, resulting in changes in capacitance and inductance between the contact points of the connector, which in turn affects the transmission of radio frequency signals.

Material quality: RF connector materials have a great impact on the degree of wear, such as metal materials, hardness, strength and process technology and other factors will affect the durability of RF connectors

Connection: Different types of RF connectors are connected in different ways. Some connectors are prone to wear and tear due to the small contact area or improper connection.

Improper maintenance: the correct maintenance of RF connectors can extend their service life, while the wrong maintenance and care, will reduce the service life of RF connectors, accelerate wear and tear.

Impact of RF Connector Wear on Performance

RF connectors can be adversely affected by wear and tear that occur during the use of the connector. Among them, the main demonstrations are as follows.

Increased signal attenuation: Wear and tear on the contact portion of the RF connector reduces the tightness and stability of the connection, which leads to an increase in signal attenuation, thus affecting the signal-to-noise ratio and signal distortion in RF signal transmission. As a result, the signal quality will decrease significantly as the transmission distance of the signal increases.

Frequency response degradation: When a connector wears out, it reduces the contact area, leading to changes in the capacitance and inductance values of the connection. This, in turn, decreases the frequency response of the connector and may result in spectral distortion.

Less frequent plugging and unplugging: RF connector wear makes plugging and unplugging less frequent, because after many plugs and unplugs, the contact part of the connector will wear more, further reducing the reliability and stability of the connection. If the connector becomes loose or destabilized, etc., it needs to be replaced with a new connector.

Reduced reliability: Problems such as wear and looseness in the contact portion of the RF connector can reduce the reliability of the connection and may lead to equipment failure or system instability. For example, in radio communications, a malfunctioning connector may prevent communications from taking place, with consequent impacts on productivity and quality.

Temperature-induced deformation: Connectors are affected by temperature in use, exacerbating the degree of wear and tear of its contact parts, leading to changes in the deformation of the contact parts, affecting the plug socket or destabilization. Such as in radio communications, connector loosening and destabilization can lead to signal distortion, which in turn brings serious interference.

Solutions to RF Connector Wear Problems

The problem of RF connector wear is common, but can be solved by.

Material selection: The material of the connector has a great influence on its durability and anti-wear ability. For example, titanium alloy, stainless steel and other materials with high hardness and strength and strong anti-rust ability can effectively extend the service life of RF connectors.

Environmental control: In the use of RF connectors, environmental factors are also a very important factor. For example, a variety of physical conditions (such as temperature, humidity, vibration, electromagnetic radiation, etc.) may have an impact on the RF connector, so the connector should be used under normal operating conditions

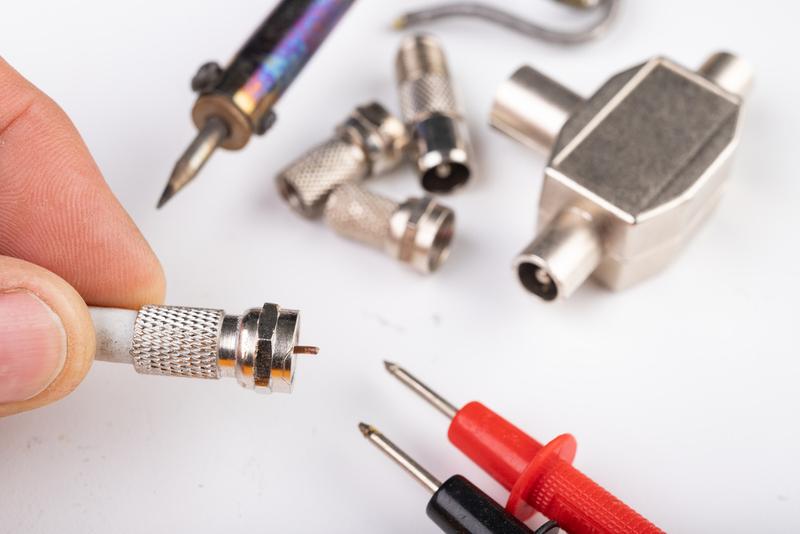

Receptacle maintenance: Effectively extending the service life of RF connectors requires proper maintenance and care. For instance, one should ensure that the connection threads remain dry and clean, maintaining the connector in a dry state and preventing the connection threads from loosening. Regularly inspect the connector, clean the connection surface to remove any dirt, and ensure a tight connection.

Selection of a suitable connector: When choosing RF connectors, one should select a suitable connector based on the requirements. For instance, in the higher frequency field, one can choose an RF connector with a superior frequency response to optimize the system’s signal transmission.

To control plugging and unplugging: In daily use, attempt to reduce the frequency of plugging and unplugging the connector to prevent connector wear and tear. For connectors that require frequent plugging and unplugging, implement appropriate protective measures, such as installing plug protection sleeves.

Conclusion

Wear and tear of RF connectors can have a large impact on their performance, so it is important to use and maintain RF connectors in the correct environment. By choosing the right material, selecting the right connector, strictly controlling the environment, and regularly inspecting and cleaning the connector, the wear of the connector can be effectively slowed down to improve its overall service life.