Radio Frequency (RF) connectors are key to transmitting RF signals and are widely used in wireless communications, microwave communications, satellite communications, radar systems and other RF equipment. This article discusses the development of RF connectors and their important applications in microwave components, taking SMP connectors as an example.

RF Connectors

RF connectors are components that are installed in cables or on instruments. They are the main element of the electrical connection in the transmission line and act like a bridge.Compared to other electronic components, the development history of RF connectors is relatively short. The earliest RF connector, the UHF connector, was introduced in 1930. During World War II, driven by the demands of the war, radar and microwave communications led to the introduction of connectors such as N and BNC. In 1958, miniaturized products like SMA and SMB were introduced. In 1964, the overall specifications for RF connectors were established. Since then, RF connectors have gradually developed towards standardization, normalization, and generalization.

Thanks to the efforts of industry experts, RF connectors have gained systematic expertise and hold an important position within the connector family. They play an indispensable role in coaxial transmission systems. A robust standard system has been established, achieving standardization of raw materials and auxiliary materials. Specialized production has also been implemented.

Impact of SMP Connectors on Microwave Components

Impact in the Assembly Process

The accuracy of the internal spacing of phased-array radar array elements is crucial for the radar’s overall performance. Achieving the specified dimensional accuracy is a central concern in assembling antenna units and microwave components. The original design of the antenna array elements, which are separate, leads to significant errors during assembly. To meet the strict accuracy standards for antenna elements and components, the SMP connector utilizes a modern, large-tolerance structure. This structure effectively reduces the pressure on matching between the microwave assembly and the antenna element.

Impact in Frequency Spacing

According to the basic principle of electrical scanning in phased-array radars, the distance between the array elements is usually the radar’s operating frequency half-wavelength. When the component frequency is raised to the Ku-band, the corresponding half-wavelength is about 8 millimeters. The outer diameter dimensions of conventional coaxial cable thread locking members exceed the channel spacing of the assembly. Often this pitch standard can only be accommodated by complex connector adapters. If a waveguide connection is used, the waveguide machining process criteria would become very demanding and complex, and productivity would be low. The smaller profile of the SMP connector significantly reduces the impact of the connector size on the endface of the T/R component.

SMP Connectors

Features

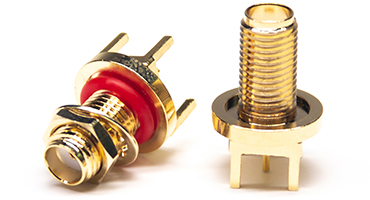

SMP is one of the many RF connectors. It is characterized by its ultra-small size, push-in design, and light weight. It allows for quick and easy plugging and unplugging. SMP connectors have excellent seismic performance and can operate over a wide range of frequencies, up to 40GHz. They are also designed to meet the standards of different frequency bands. SMP products are commonly used in microwave devices that require multiple simultaneous insertions on a board.

Selection for Use

SMP connectors can be installed in a variety of ways, each of which has its own characteristics, and the most suitable way can be selected according to the usage requirements and space size.

Flange mount: Easy to install and connect.

Threaded connection: Advantage is easy to install, occupies little space.

Solder: Good sealing and occupies minimum space.

Maintenance Methods

Connector contamination and damage typically decrease measurement accuracy. It is important to clean connectors thoroughly after use to prevent contamination and damage from dirt and metal particles. This ensures that the connectors are always in optimal working condition. If possible, it is recommended to use compressed air, as it effectively removes dust particles without causing any harm to the connector bonding surface. In cases where compressed air cannot eliminate dust and oil residues, isopropyl alcohol can be used for specific wiping processes. Care should be taken to avoid applying excessive force, which could lead to connector conductor deformation and damage.

Additionally, it is advisable to prevent the solvent from coming into contact with the insulation dielectric layer. When the solvent on the connector surface is completely dry, it is advisable to store it properly. This is particularly important for RF connectors, especially those used in microwave frequencies. When the connector is not in use, it is advisable to protect the end of the connector with a plastic guard to avoid interface contamination. Furthermore, it is recommended to store the connector in a box that has a foam groove arrangement inside. This arrangement helps prevent any potential mechanical damage issues from occurring.